*Industry Knowledge Development*A pneumatic solenoid valve is an electrically controlled valve that uses a solenoid to control the flow of compressed air in a pneumatic system. It is a type of electromechanical valve that is commonly used in industrial automation applications to control the flow of air in pneumatic systems.

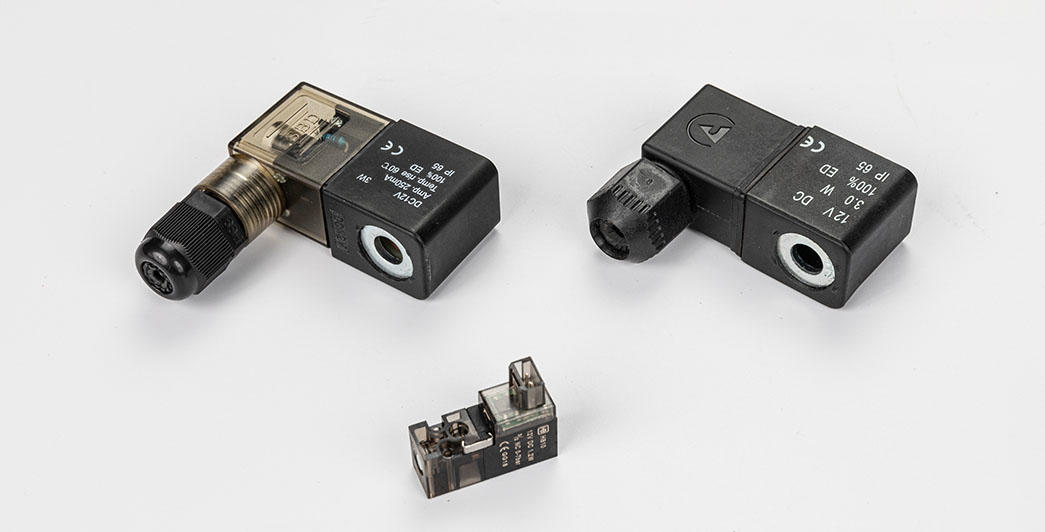

The valve is composed of a solenoid coil and a valve body, which contains the valve's internal components. When an electrical current is applied to the solenoid coil, it generates a magnetic field that moves a plunger inside the coil. The plunger is attached to a valve spool or poppet, which opens or closes the valve by allowing or blocking the flow of compressed air.

Pneumatic solenoid valves are commonly used in applications such as controlling the operation of pneumatic cylinders, controlling the flow of air in air-operated tools, and controlling the flow of air in industrial processes. They are preferred over manual valves as they can be controlled remotely, and can operate much faster and more precisely than manual valves. They are also more reliable and require less maintenance, making them a cost-effective solution for many industrial applications.

Here are some characteristics of pneumatic solenoid valves:

1.Electrically operated: Pneumatic solenoid valves are operated by an electric current. The current is used to energize a coil that creates a magnetic field. This magnetic field then moves a plunger, which opens or closes the valve.

2.Quick response time: Pneumatic solenoid valves have a fast response time, which means they can switch from one position to another quickly. This is important in applications where rapid changes in flow are needed.

3.Simple design: Pneumatic solenoid valves have a simple design, which makes them easy to install and maintain. They consist of a coil, a plunger, and a valve body.

4.Low power consumption: Pneumatic solenoid valves require very little power to operate, which makes them energy-efficient. This is because the valve only needs power when it is changing position.

5.Versatile: Pneumatic solenoid valves can be used in a wide range of applications, including air compressors, vacuum systems, and hydraulic systems.

6.Precise control: Pneumatic solenoid valves provide precise control over fluid flow. They can be used to regulate flow rate, pressure, and direction.

7.Reliability: Pneumatic solenoid valves are highly reliable and can operate for long periods without maintenance. This makes them a popular choice in industrial applications.

There are several types of pneumatic solenoid valves available, including:

2-way normally closed: This type of valve has two ports and is normally closed, meaning that the valve is closed in the resting state and opens when the solenoid is energized.

2-way normally open: Similar to the 2-way normally closed valve, this type of valve has two ports but is normally open, meaning that the valve is open in the resting state and closes when the solenoid is energized.

3-way normally closed: This type of valve has three ports and is normally closed, meaning that the valve is closed in the resting state and opens to allow flow between two of the ports when the solenoid is energized.

3-way normally open: Similar to the 3-way normally closed valve, this type of valve has three ports but is normally open, meaning that the valve is open in the resting state and closes to block flow between two of the ports when the solenoid is energized.

4-way: This type of valve has four ports and is commonly used for controlling double-acting pneumatic actuators. It can be configured as either a 4-way, 2-position valve or a 4-way, 3-position valve.

Direct-acting: In a direct-acting solenoid valve, the solenoid directly controls the opening and closing of the valve without the need for a separate pilot valve.

Pilot-operated: In a pilot-operated solenoid valve, the solenoid controls a small pilot valve that in turn controls the opening and closing of the main valve. This type of valve is typically used for larger valves or in applications with high pressure or flow rates.

Diaphragm: A diaphragm solenoid valve uses a flexible diaphragm to control the flow of fluid. When the solenoid is energized, it lifts the diaphragm and allows fluid to flow through the valve.

中文简体

中文简体 English

English Français

Français 日本語

日本語 Deutsch

Deutsch