*Industry Knowledge Development*Air check valves are devices used to control the flow of air in a system, ensuring that air flows in only one direction. They are commonly used in pneumatic systems to prevent backflow of air, which can cause damage or reduce the efficiency of the system.

Air check valves work by allowing air to flow freely in one direction, but preventing it from flowing in the opposite direction. They typically consist of a valve body with an opening that allows air to flow through, and a movable component, such as a ball or a disc, that blocks the opening when air flows in the opposite direction.

There are various types of air check valves, including ball check valves, swing check valves, and diaphragm check valves. The choice of valve type depends on the specific application and the operating conditions of the system.

Air check valves are widely used in various industries, including HVAC, automotive, and manufacturing. They are an essential component of many pneumatic systems, helping to maintain system efficiency and prevent damage.

Choosing the right air check valve depends on several factors, such as the application, the flow rate, the pressure range, and the materials of construction. Here are some guidelines to help you choose the right air check valve:

Application: Determine the purpose of the air check valve, such as preventing backflow, controlling flow direction, or preventing fluid from siphoning. This will help you select the right type of air check valve, such as a swing check valve, lift check valve, or ball check valve.

Flow rate: Consider the flow rate of the fluid or gas that will pass through the valve. This will help you select the right size of the valve to ensure that it can handle the required flow rate.

Pressure range: Determine the pressure range of the fluid or gas that will pass through the valve. This will help you select the right pressure rating of the valve to ensure that it can withstand the required pressure.

Materials of construction: Consider the compatibility of the valve materials with the fluid or gas that will pass through it. For example, if the fluid is corrosive, you will need a valve made of a corrosion-resistant material such as stainless steel or PVC.

Environment: Consider the operating environment of the valve, such as the temperature, humidity, and exposure to chemicals or UV light. This will help you select a valve that is suitable for the operating conditions.

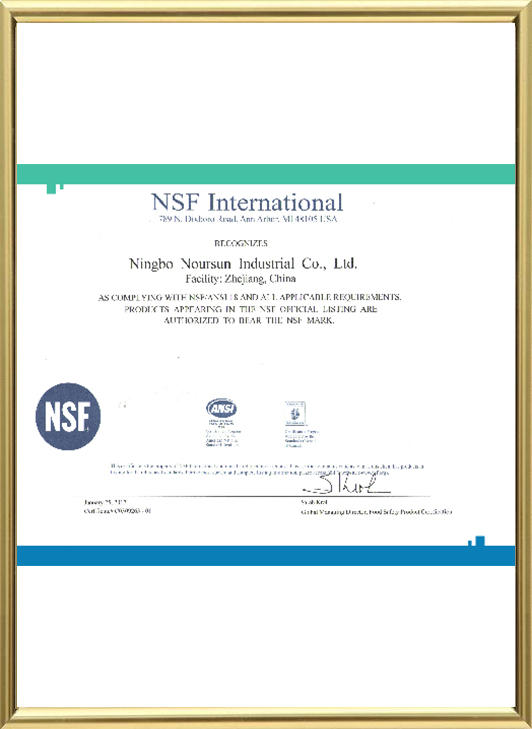

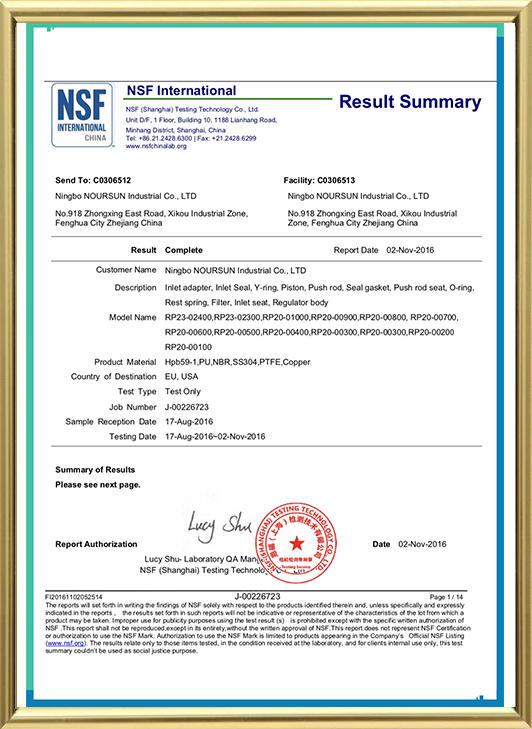

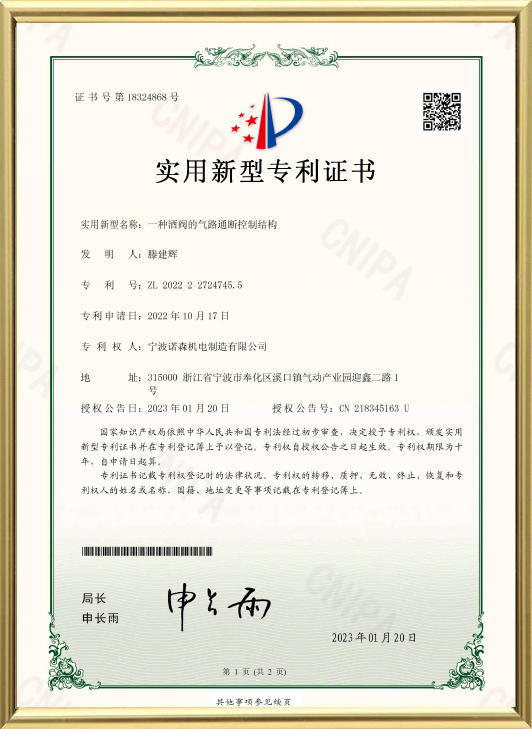

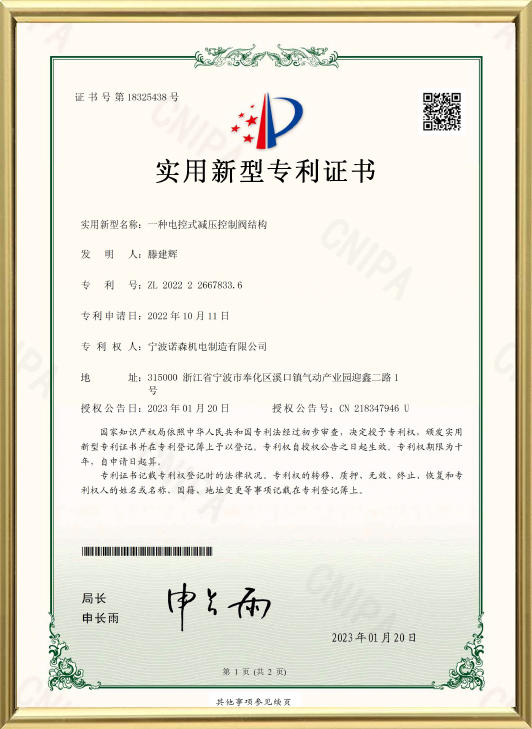

Standards and certifications: Ensure that the valve meets relevant industry standards and certifications, such as ANSI, API, or ISO, to ensure its quality and performance.

By considering these factors, you can select the right air check valve for your specific application. It's also recommended to consult with a valve supplier or manufacturer to ensure that you select the most suitable valve for your specific requirements.

Here are some general steps to use air check valves:

1.Identify the correct placement of the air check valve in the system.The valve should be installed in the pipe or tubing that carries air or gas, with the arrow on the valve indicating the direction of the airflow.

2.Ensure that the valve is compatible with the system's pressure and temperature requirements. Check the manufacturer's specifications to determine the maximum allowable pressure and temperature for the valve.

3.Install the valve in the system, making sure to follow any instructions provided by the manufacturer. The valve should be securely mounted to prevent any leaks.

4.Check the valve periodically to ensure that it is functioning properly.If there is any air or gas flow in the opposite direction, the valve may be faulty and should be replaced.

5.If the valve needs to be replaced, follow the manufacturer's instructions for removal and installation.

It's essential to follow the manufacturer's instructions for the specific air check valve you are using to ensure proper installation and operation.

中文简体

中文简体 English

English Français

Français 日本語

日本語 Deutsch

Deutsch