*Industry Knowledge Development*

Pressure regulators are devices that control the pressure of a gas or liquid in a system. They are used in a wide variety of industrial, commercial, and residential applications where precise pressure control is critical for safety, efficiency, and effectiveness.

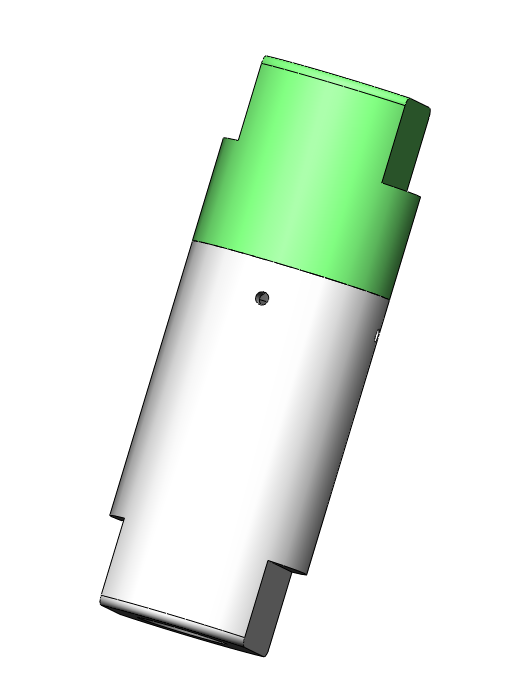

The basic function of a pressure regulator is to reduce the inlet pressure to a lower, more stable outlet pressure. This is accomplished by using a spring-loaded diaphragm or piston mechanism that responds to changes in pressure to maintain a consistent output pressure. Pressure regulators are typically made of brass, stainless steel, or other durable materials, and they may have various types of connections, such as threaded, flanged, or welded.

Pressure regulators can be classified into two main types: single-stage and two-stage. Single-stage regulators provide a fixed pressure reduction from the inlet to the outlet, while two-stage regulators provide a more precise and stable pressure reduction over a wider range of inlet pressures. Two-stage regulators are often used in applications where a consistent pressure is critical, such as in medical and laboratory settings.

Pressure regulators can also be categorized based on the type of gas or liquid they are designed to control, such as oxygen, nitrogen, propane, or natural gas. Some pressure regulators are designed for high-pressure applications, while others are suitable for low-pressure applications.

There are several types of pressure regulators, including:

Single-stage regulators: These regulators reduce pressure from a high-pressure source to a lower working pressure in a single step.

Two-stage regulators: These regulators reduce pressure in two steps, providing a more precise and stable output pressure over a wide range of input pressures.

Differential pressure regulators: These regulators control the pressure drop across a system or component, maintaining a constant flow rate regardless of changes in upstream or downstream pressure.

Back pressure regulators: These regulators maintain a constant pressure on the outlet side of a system, even as the inlet pressure varies.

High-pressure regulators: These regulators are designed to handle high-pressure gas or liquid streams, typically for industrial or process applications.

Low-pressure regulators: These regulators are designed for low-pressure applications, such as propane or natural gas appliances.

Vacuum regulators: These regulators control the pressure in a vacuum system, typically by throttling the flow of gas or liquid into the system.

Self-operated regulators: These regulators use the process fluid itself to control the pressure, without requiring external power or control signals.

The specific type of pressure regulator used depends on the application and the requirements for pressure control, accuracy, and reliability.

The following are some common characteristics of pressure regulators:

Pressure range: Pressure regulators have a specific range of pressures that they are designed to work within. This range is usually stated on the regulator and can vary from a few psi to thousands of psi.

Flow rate: The flow rate of a pressure regulator is the amount of fluid or gas that it can regulate in a given time period. This rate is determined by the size of the regulator and the pressure range it is designed to work within.

Accuracy: The accuracy of a pressure regulator refers to how closely it can regulate the pressure to a specific set point.

Response time: The response time of a pressure regulator is the time it takes for the regulator to adjust the pressure to the desired set point. This time can vary depending on the size of the regulator and the pressure range it is designed to work within.

Pressure relief: Pressure regulators may have a pressure relief feature that will vent excess pressure to prevent damage to the system or the regulator itself.

Material compatibility: The materials used in the construction of pressure regulators must be compatible with the fluid or gas being regulated. This is important to prevent corrosion or contamination of the fluid or gas.

Maintenance: Pressure regulators may require periodic maintenance to ensure that they are functioning properly. This may include cleaning or replacing components such as filters or diaphragms.

Mounting options: Pressure regulators may be designed for specific mounting options, such as panel mount or inline mounting.

Adjustability: Most pressure regulators allow for adjustment of the set point pressure to accommodate changes in the system requirements.

Temperature range: Pressure regulators may have a specific temperature range in which they can operate. This range is usually stated on the regulator and may be limited by the materials used in its construction.